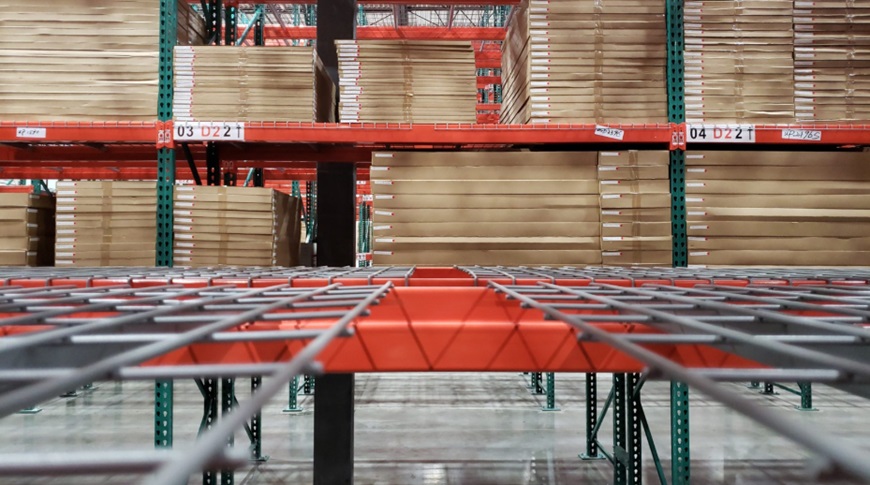

A wire deck plays a crucial role in improving safety and stability across warehouse environments. Whether you’re storing heavy merchandise, boxed goods, or irregular-shaped inventory, wire deck pallet systems add an extra layer of protection beneath each pallet while reinforcing overall rack performance. Warehouses today demand flexible and secure storage solutions that reduce accidents and product damage. Wire decking delivers on both fronts, serving as a load support mechanism that prevents misplaced or broken pallets from falling through racking systems.

Structural Stability for Safer Storage

Wire decking distributes the weight of stored goods more evenly across pallet rack beams. This reduces stress on individual pallet boards and prevents sagging or breakage under heavy loads. By reinforcing load-bearing capacity, wire decking supports warehouse safety protocols and prevents load shifts that could otherwise lead to spills, collapses, or injuries.

One of the most important safety features of a wire deck for pallet systems is its open-mesh design. Unlike solid surfaces, wire decks allow for better air circulation and improved visibility, which is especially beneficial for fire suppression systems and workplace inspections. The open grid also prevents dust buildup and moisture accumulation, reducing fire risk and promoting cleanliness in high-volume storage areas.

Additionally, various styles of wire decking can accommodate both standard and non-standard pallets, adding flexibility without sacrificing security. A well-fitted wire deck minimizes product movement during loading and unloading, especially when forklifts or order pickers are involved.

Warehouses looking to improve safety performance must understand not just the visual or mechanical benefits of wire decking but also how it reinforces the entire racking system’s functionality. The benefits of wire decking for warehouse pallet racking, include how it helps reduce product loss and improve operational efficiency.

Versatility That Supports Modern Inventory Needs

Wire decking also enhances the adaptability of pallet racking systems. With adjustable beam levels, businesses can quickly reconfigure rack heights and shelf spacings while still enjoying full-load support. The deck acts as a universal base that supports goods whether or not a pallet is used.

When used with dividers or bins, wire decks help organize SKUs efficiently, contributing to faster order picking and more accurate stock counts. Their modular design means wire decks can be removed, replaced, or repositioned with ease, making them ideal for dynamic warehouse layouts.

In environments where various product sizes and weights are stored, wire deck for pallets enhances flexible storage configurations by providing consistent support regardless of item type. This adaptability is essential in operations that deal with seasonal products, rotating stock, or growing inventory demands.

Wire decks also improve compliance with OSHA and fire code standards due to their open structure, ensuring businesses can pass inspections without costly racking modifications or replacements.

Conclusion

Investing in wire decking is not just a structural decision, it’s a proactive safety strategy. From reducing rack failure risks to enhancing fire protection and improving operational flow, wire decking provides numerous benefits that directly impact warehouse safety and efficiency. Durable, versatile, and compliant with modern warehouse standards, it ensures your pallet racking systems perform optimally under all conditions. For any business managing high-volume or varied inventory, wire decking is a simple yet powerful upgrade that supports long-term stability and safety.